Pipercross Performance Intake System

Take your vehicle's performance to the next level with Pipercross Performance Induction Systems. Meticulously designed induction systems are tailored to your specific vehicle, providing a bespoke solution for maximizing power, efficiency, and induction sound.

Pipercross VAG 2.0TFSI Intake System

The Pipercross Intake System has been designed and engineered to directly replace the OEM airbox and integrated intake plumbing on VAG cars fitted with the 2.0TFSI engine.

KEY FEATURES

- Large filter heatshield utilising OE cold air duct

- Bespoke Pipercross conical air filter utilising market-leading foam filtration media

- Single piece mandrel bent aluminum intake pipe

- Thick-walled silicones with smooth step internals

- Designed, prototyped and iteratively refined using latest 3D scanning and CAD technology

- Dyno tested with proven power gains of +15 WHP/ +21 NM Tq

OEM INTAKE ASSESSMENT

The OEM intake system found on VAG cars fitted with the 2.0TFSI engine (found in various VAG chassis vehicles between 2003>2013) features several performance-focused aspects that are indicative of this era of VAG cars. This engineering allows the OE intake parts to adequately support the 2.0TFSI engine in most scenarios, when the engine is operating with OE ECU programming. However, aftermarket engine tuning (even conservative tuning) increases boost (and subsequent turbocharger air demand) enough that the OE intake components begin to limit performance of the engine, even in typical driving scenarios.

The Pipercross engineering team identified the OE intake filtration media type/total surface area, OE airbox and the airbox-integrated plumbing as areas of potential system performance improvement, especially considering the integrated air filter in the engine cover.

Filtration media/surface area was to be improved via a custom conical, foam-based air filter produced in-house at Pipercross. The airbox and the respective integrated plumbing were to be wholly replaced with an aluminium heatshield and hard pipe assembly that optimised usage of the OE fresh-air ducting, while isolating this fresh air from ambient engine heat. All Pipercross components were to be maximised (filter size, partitioned heatshield space, hard pipe/hose diameter) for the available engine volume, without compromising clearance standards required for the long-term durability of the kit.

CONICAL AIR FILTER

The heart of the Pipercross intake kit is the Pipercross conical air filter. This filter features Pipercross’ time-tested and proven air filter construction methods, to achieve the targeted airflow performance of the kit while maintaining the headroom required to support significant future tuning packages/hardware upgrades. The bespoke Pipercross foam filtration media blend strikes the perfect balance between increased flow and air filtration, while the large radius spinning, optimised for airflow draws from decades of successful in-house Pipercross filter manufacturing. The utilisation of a conical filter increases filtration surface area 10.14% over a typical panel filter and features a 180mm OD filter with a 90mm diameter spun aluminium outlet. This filter serves as the foundation for the performance increase offered by the Pipercross intake kit.

HEATSHIELD

The Pipercross heatshield was meticulously designed to maximise the shielded volume within TFSI engine bays, while optimising the use of the OE fresh-air ducting - thus maximising the performance of the air filter. The part fully shields the filter from ambient engine heat with a four-wall design towards the engine, fully insulating the cavity from heated air ingress. The lower portion of this four-wall design is tailored to the OE fresh-air ducting, with off-plane bends designed to shape the fresh air flow from the OE ducting throughout the enclosed space (and distribute across the lower portion of the Pipercross filter, as such). The Pipercross heatshield is CNC laser cut from corrosion-resistant 1.5mm aluminium sheet and powder coated for additional corrosion resistance/aesthetic appeal. To further assure the long-term durability of the Pipercross parts, hybrid EPDM edging trim is used to isolate the heatshield from direct contact with any other components - preventing any vibration-related part failures.

HARD PIPE

The Pipercross 2.0TFSI hard pipe assembly supplements the benefits offered by the air filter and heatshield, rounding out the overall performance capabilities of the Pipercross kit. The assembly is constructed of a single-piece, 90mm outer diameter aluminium tube that has been CNC mandrel-bent with optimal radius bends, for a consistent internal cross-sectional flow area throughout the tubing. The end of the Pipercross hard pipe assembly features a 70mm outer diameter reducing swage, to properly connect with the OE turbocharger inlet hose while maintaining the single-piece tube construction. MAF sensor placement was also carefully considered, with a CNC-machined sensor boss placed in an almost identical location to the OE plumbing (to ensure consistent and accurate sensor readings with the Pipercross kit installed). The pipe assembly also features an integrated mounting point designed to accept a vibration-isolating mount, to eliminate the potential of part failure due to long-term weld/tubing vibration-based loading. Finally, each assembly is powder coated to stringent specifications for additional corrosion resistance and aesthetic appeal, without any internal bore/boss overcoating.

DETAILS

The subtle details of the Pipercross Intake Kit are what elevate it beyond the competition. The silicone turbo elbow has provisions for both KO3 and KO4 equipped cars with different DV locations, custom CNC machined blanking plug and joiner are included for each application. The coupling and elbow hoses feature a smooth internal bore and 5-ply wall construction; ensuring long term durability without any of the airflow destabilization associated with typical corrugated couplers. All Pipercross brackets are CNC laser cut from steel plate and powder coated to match; for better long-term fatigue/failure and corrosion resistance. All stainless-steel hardware is provided to ensure corrosion, oil and other adverse engine bay environmental factors have no effect on the Pipercross kit’s function or aesthetic – no matter how hard the vehicle is driven.

RESEARCH AND DEVELOPMENT

All Pipercross products are designed in-house, utilising the latest 3D-printing, 3D-scanning, CAD, CFD, airflow testing and performance testing product development technologies. The Pipercross 2.0TFSI Intake Kit saw several design stages/iterations, to integrate the largest air filter, shielded engine bay volume and intake pipe diameter possible, while maintaining required part clearances. Bench airflow testing was conducted on the full OEM intake system and the final Pipercross intake design, using Pipercross’ in-house, custom designed and built airflow test apparatus inside a controlled environment. Performance testing of the OEM and final Pipercross intake design was completed at a third party, independent, environmentally regulated Dyno Dynamics four-wheel drive dynamometer cell; to ensure unbiased performance gain data was captured.

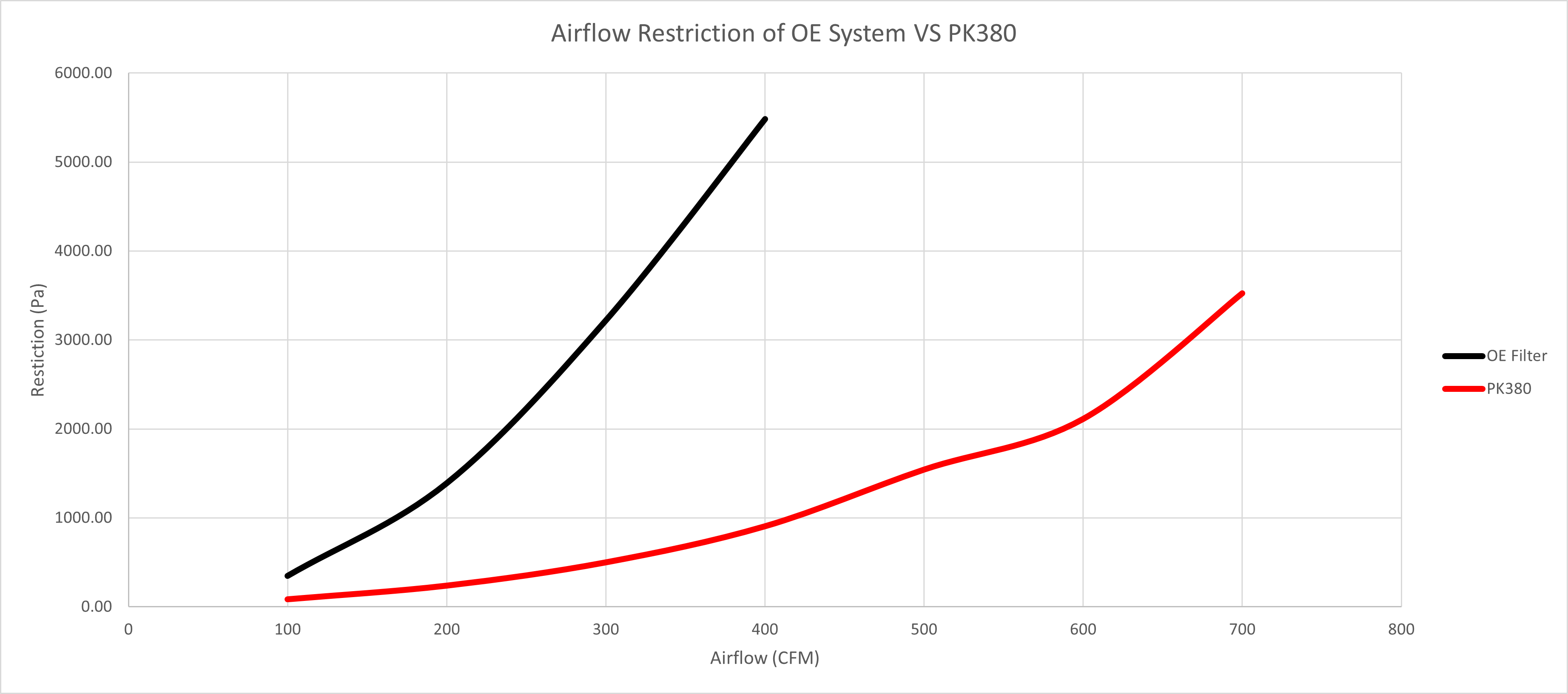

AIRFLOW TESTING DATA

Both the OE and final Pipercross intake configurations were tested on Pipercross’ in-house, custom built stationary airflow test apparatus. To develop an initial airflow baseline, the OE intake system was tested to its maximum airflow value. The complete final Pipercross intake system was then tested to its maximum flow value. The graph below summarize the results of this testing, illustrating the Pipercross kit’s 146% maximum decrease in airflow restriction (and thus confirming the performance benefit of Pipercross intake components). The maximum airflow values for both the full Pipercross and OE intake systems are of note as well; the Pipercross system supported up to 746 CFM, while the OE system supported up to 481 CFM (a 43% increase, respectively).

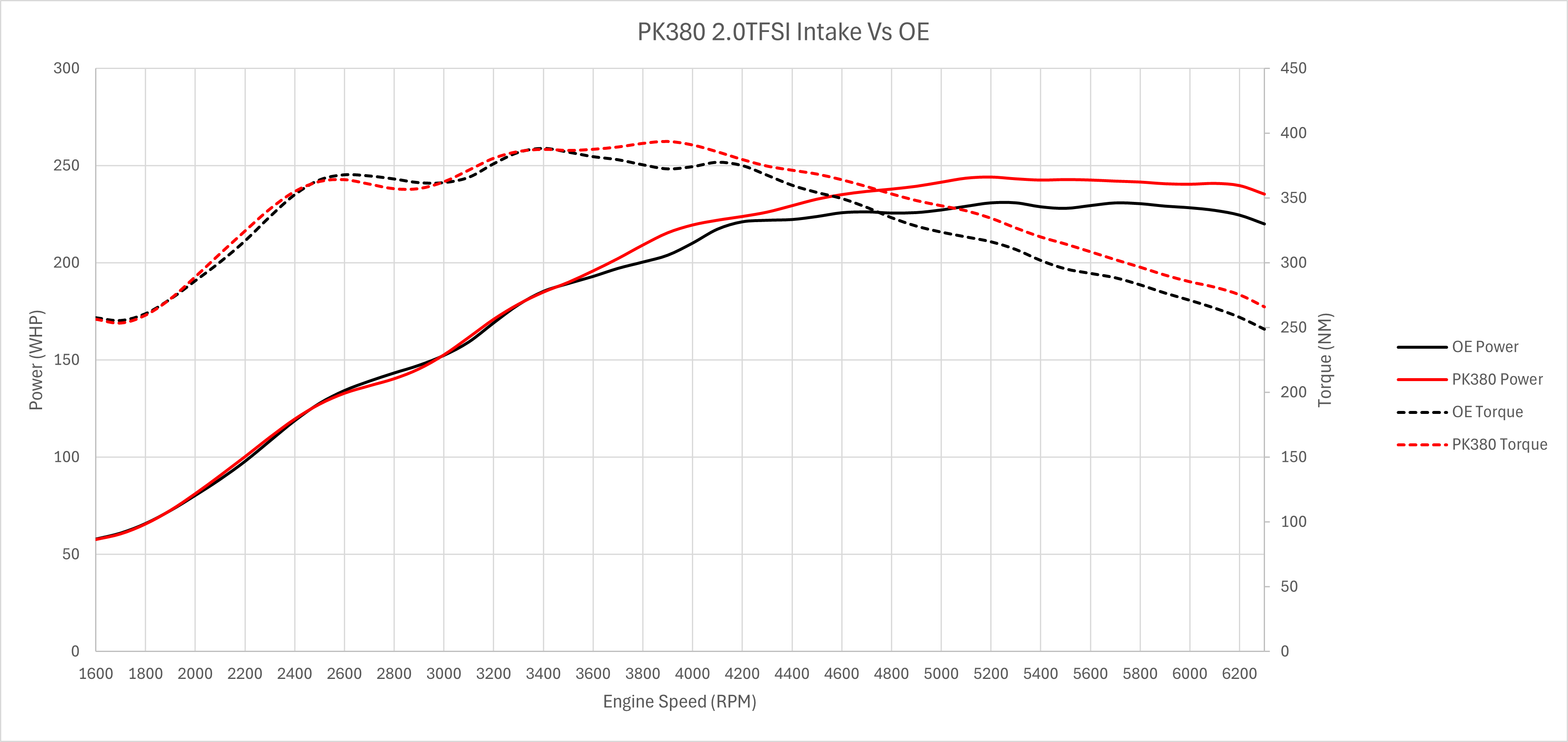

PERFORMANCE TESTING DATA

Building upon the data gathered from the airflow testing, the final version of the Pipercross intake kit was tested on a 2009 VW Golf GTI (2.0TFSI engine) with stage 1 software. The performance testing was conducted utilising a third-party, independent Dynapac four-wheel drive hub dyno within a temperature and airflow-controlled test cell. Three runs of each intake configuration (six runs in total) were tested on the same day, within the same cell and the vehicle was allowed to cool between testing sets.

The data displayed shows the average of three runs for each intake configuration. As clearly visible within the data sets, the Pipercross intake kit provides significant performance benefit to the 2.0TFSI throughout the engine’s speed range. Of particular note is the large power delta at the top of the engine’s speed range, as well as the large torque delta (and location of the maximum torque gained) within the most usable part of the engine’s speed range (3600-5200 RPM) – both indicating that the drivability of the vehicle with the Pipercross intake installed is significantly improved.

*Dyno data accurate on day of testing, results may vary.

COMPATIBLE VEHICLES

- Audi, A3 (8P), 2.0 TFSI, 2006 - 2012 (EA113 models ONLY)

- Audi, S3 (8P), 2.0 TFSI, 2006 - 2012

- Seat, Leon MK2, 2.0 TFSI, 2005 - 2012

- Seat, Altea, 2.0 TFSI, 2006 - 2009

- Skoda, Octavia Mk2, 2.0 TFSI, 2005 - 2013 (EA113 models ONLY)

- VW, Golf MK5, 2.0 TFSI, 2003 - 2009

- VW, Golf MK6 (R, ED35), 2.0 TFSI, 2008 - 2013 (EA113 models ONLY)

- VW, Scirocco R, 2.0 TFSI, 2008 - 2018 (EA113 models ONLY)

- VW, Jetta, 2.0 TFSI, 2006 - 2010

FITTING INSTRUCTIONS

- Click HERE to download fitting instructions.

Customers Also Viewed

Not quite what you're looking for? Try what other customers are looking at.